Digital transformation is no longer a futuristic promise – it’s already happening, and every day, artificial intelligence (AI) is proving to be the driving force behind this change. Industries that have traditionally been seen as slow to adapt to innovation are undergoing a quiet but profound revolution. If you haven’t yet noticed the impact of this technology on the industrial sector, prepare to be awakened: the AI revolution in manufacturing is here, and it could define the future of business.

The new industrial paradigm

In the current scenario, competitiveness is not measured solely by operational efficiency, but by the ability to innovate and adapt quickly. AI has established itself as one of the pillars of this transformation, promoting improvements ranging from process automation to predictive analysis and equipment maintenance. If you, as a manager or entrepreneur, want to be one step ahead, it is essential to understand how this revolution impacts industries.

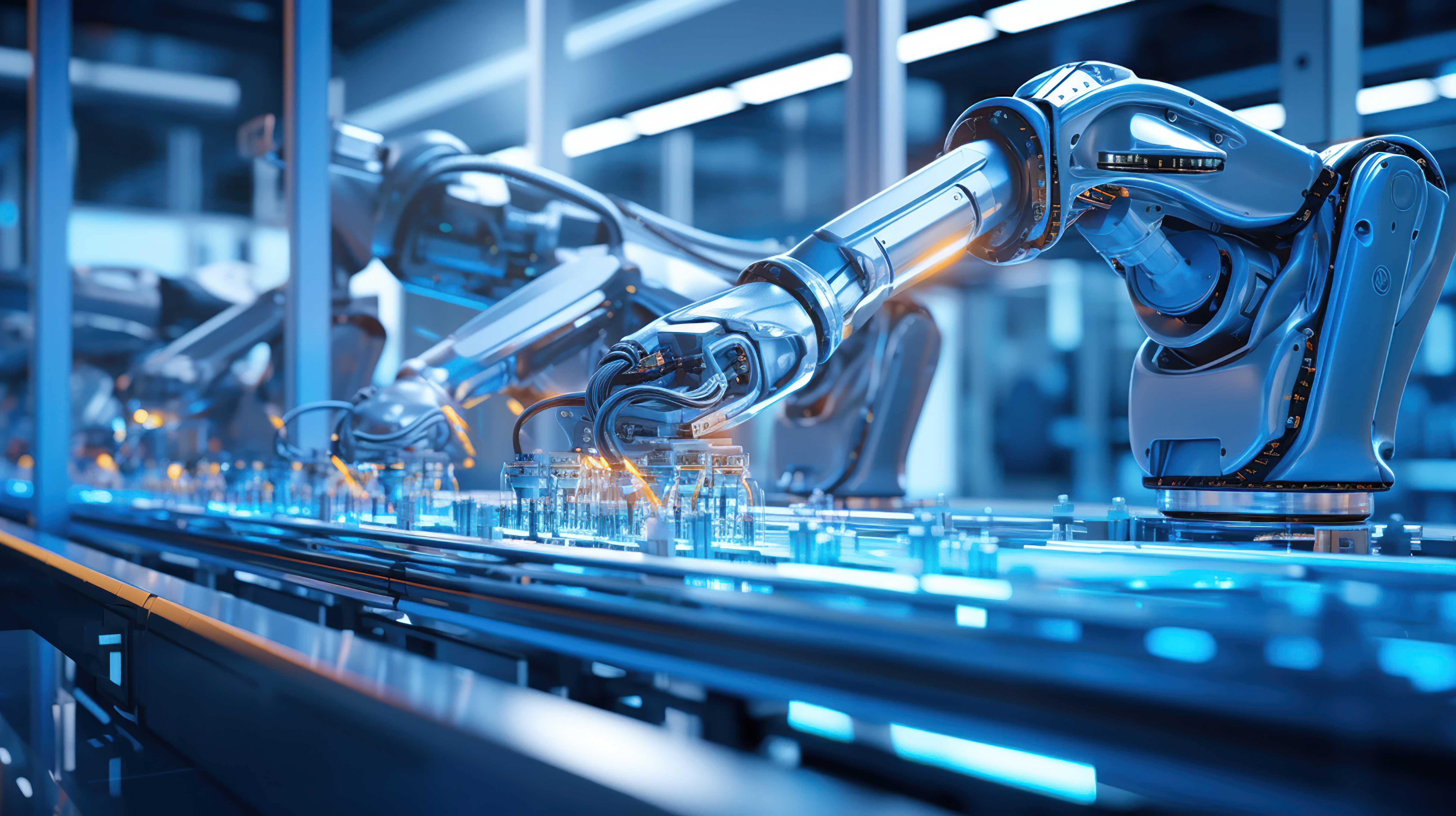

Imagine a factory where robots not only perform repetitive tasks, but also monitor and predict equipment failures, adjusting processes in real time. This is not science fiction – it is the practical result of the intelligent use of AI . And the best part is that the benefits go far beyond simple time or cost savings. They include product quality, worker safety and, most importantly, business sustainability.

What is Artificial Intelligence and why is it crucial for industries

Artificial intelligence refers to systems or machines that mimic human intelligence to perform tasks and can iteratively improve themselves based on the information they collect. In industry, this ability is applied to optimize processes, identify patterns, and make decisions based on real data – all with precision and speed that humans would struggle to achieve.

Key aspects of AI in industries:

-

Automation and Operational Efficiency:

AI enables the automation of repetitive and dangerous tasks, freeing up employees for more strategic roles. This results in greater efficiency and reduced operational errors. -

Predictive Maintenance:

With algorithms that analyze machine behavior, it is possible to predict failures before they occur. This approach not only increases the useful life of equipment but also reduces costs with emergency maintenance. -

Supply Chain Optimization:

Analyzing large volumes of data allows for a detailed view of the entire production chain, facilitating demand forecasting, inventory management and logistics – essential factors for competitiveness. -

Quality and Process Control:

Intelligent systems monitor production in real time, ensuring product quality and quickly identifying deviations in processes. -

Innovation and New Product Development:

AI’s analytical capabilities enable the creation of innovative solutions, transforming data into insights that can lead to the development of new products and processes.

Benefits of AI for Industries: A Game Changer

Implementing AI brings a series of tangible benefits that go beyond simple automation. It creates a synergy between machines and humans, enhancing companies’ capacity for innovation and competitiveness. Let’s explore some of the most impactful benefits:

1. Cost Reduction and Increased Productivity

Process automation eliminates the need for manual intervention in routine tasks, which reduces errors and increases productivity. Fewer errors mean less waste of resources and, consequently, a significant reduction in costs . Companies that adopt AI are able to transform large volumes of data into practical and efficient actions, maximizing operational results.

2. Improvement in Product Quality

Real-time monitoring systems identify any deviations in production parameters, allowing immediate corrections. This approach ensures that every product leaving the production line meets the highest quality standards. This strengthens the brand reputation and significantly increases customer satisfaction .

3. Predictive Maintenance: The Future of Equipment Management

Emergency maintenance not only interrupts production, but also increases operating costs. AI enables continuous analysis of equipment, identifying signs of wear or imminent failure. This enables preventive maintenance to be scheduled, ensuring operational continuity and avoiding unexpected losses.

4. Safety in the Workplace

By taking on dangerous or unhealthy tasks, AI- based systems contribute to employee safety. Reducing operational risks is a benefit that goes beyond numbers: it is a matter of valuing human life and promoting a safer and healthier work environment.

5. Data-Driven Decisions: The Power of Information

In a market where speed and accuracy of decisions make all the difference, data analysis becomes crucial. AI integrates information from different points in the production chain, allowing managers to make strategic decisions based on real data and valuable insights. This approach increases the agility and effectiveness of business strategies.

Practical examples: AI revolutionizing industrial sectors

Below, see some real cases that illustrate how artificial intelligence is being successfully applied in industries:

Case 1: Smart Factories

In many manufacturing industries, the implementation of AI systems has enabled the creation of so-called “smart factories.” In these environments, robots equipped with advanced sensors monitor each stage of production, identifying problems in real time and automatically adjusting processes. The result? A more agile production line, with less waste and higher-quality products.

Case 2: Predictive Maintenance in the Automotive Industry

Major automakers are already using AI algorithms to monitor the performance of their machines and predict potential failures. Sensors installed in critical equipment continuously send data, which is analyzed by intelligent systems. When an anomaly is detected, preventive maintenance is scheduled before a catastrophic failure occurs, avoiding production downtime and reducing costs.

Case 3: Supply Chain Optimization

Logistics and distribution companies are leveraging the power of AI to streamline their operations. By analyzing real-time and historical data, these systems can predict demand, optimize delivery routes, and accurately manage inventory. This approach not only improves efficiency, but also reduces logistics costs and increases customer satisfaction.

Case 4: Automated Quality Control

In industries such as food and pharmaceuticals, AI is used to ensure that each product meets rigorous quality standards. Intelligent cameras and sensors inspect products during production, identifying any flaws or inconsistencies. This allows for immediate intervention and process correction, ensuring the integrity of the final product.

Challenges and resistance in implementing AI in industries

While the benefits are many, the adoption of AI in industries also faces significant challenges. Among them, we can highlight:

1. Initial Cost and Return on Investment

Implementing advanced AI systems requires a considerable initial investment. Companies need to carefully analyze the expected return and plan the transition without compromising current operations. However, the gains in productivity and efficiency tend to offset the investment in the medium to long term.

2. Resistance to Change

Organizational culture is often a barrier to innovation. Employees and managers accustomed to traditional methods may resist adopting new technologies. The key to overcoming this barrier is to invest in training and demonstrate, with practical examples, how AI can make daily work easier and improve results.

3. Data Security and Privacy

Collecting and analyzing large volumes of data raises security and privacy concerns. Industries need to ensure that AI systems comply with data protection regulations and that sensitive information is adequately protected from unauthorized access.

4. Integration with Legacy Systems

Many industries operate with legacy systems that were not designed for the digital age. Integrating AI into these infrastructures can be a technical and logistical challenge. A gradual approach, starting with areas that do not rely on complex integrations, can be an effective strategy to overcome this barrier.

Strategies for implementing Artificial Intelligence in industries

Once the challenges have been overcome, AI implementation can be divided into well-defined stages. Here’s how to proceed:

A. Diagnosis and Strategic Planning

-

Map Processes:

Conduct a detailed analysis of existing processes and identify which areas can be optimized by AI . Evaluate everything from production to logistics and quality control. -

Set Clear Objectives:

Set specific goals – whether it’s to reduce costs, improve efficiency or increase product quality. Clear objectives help measure the success of the implementation.

B. Choosing the Right Tools and Partnerships

-

Research Solutions: There are several AI

tools and platforms on the market. Evaluate the available options and choose the one that best fits your industry’s specific needs. -

Strategic Partnerships:

Consider collaborating with startups or technology-focused companies. Partnerships can speed up the implementation process and provide specialized technical support.

C. Team Training and Qualification

-

Continuous Training:

Invest in courses, workshops and training so that your team understands not only how AI works , but also the possibilities for practical application. -

Create a Culture of Innovation:

Encourage employees to experiment with new tools and think outside the box. A well-trained and motivated team is essential for the success of digital transformation.

D. Gradual Integration and Continuous Monitoring

-

Phased Implementation: Start AI

integration in specific areas, monitoring results and adjusting strategies as needed. -

Performance Assessment:

Use performance indicators to measure the impacts of technology on production, quality and operating costs. Adjust processes based on constant feedback.

The future of industries in the era of Artificial Intelligence

The AI revolution is not a passing fad – it is reshaping the way industries operate and compete in the global marketplace. As technology advances, we will see innovations that today seem like science fiction become common practice on the production line.

Trends for the future:

-

Integration with IoT and Big Data:

The convergence of AI , the Internet of Things (IoT) and Big Data will enable even more accurate analysis of industrial processes. The combination of these technologies will enhance forecasting capabilities and optimize operations, creating an integrated and intelligent ecosystem. -

Mass Customization:

Customized production, where products are tailored to individual customer needs, will become a reality. AI will enable mass customization while maintaining efficiency and reducing waste. -

Sustainability and Circular Economy:

With growing environmental concerns, industries are seeking solutions that promote sustainability. AI can optimize the use of resources, minimize waste, and even help create circular economy models, where waste from one process becomes input for another. -

New Business Models:

Digitalization and intensive use of data will open up space for innovative business models. Companies that know how to adapt their strategies and integrate AI intelligently will have a decisive competitive advantage in the market.

The time to act is now!

The artificial intelligence revolution in industries doesn’t wait for anyone. If you want your company or business to stand out in an increasingly competitive scenario, it’s time to embrace this transformation. Every technological advance represents an opportunity to innovate, reduce costs and improve the quality of your products.

Remember: AI adoption is more than just modernization—it’s a mindset shift. It takes courage to abandon outdated methods and invest in solutions that truly transform the way we work. Those who hesitate risk being left behind while their competitors reap the rewards of streamlined, intelligent, and innovative operations.

So, assess your operations, identify areas for improvement, and start the process of integrating artificial intelligence into your industry today. The future belongs to those who adapt and innovate. Don’t let resistance to change stop you from making progress – the revolution has already begun, and the choice to be a part of it is in your hands.